-40%

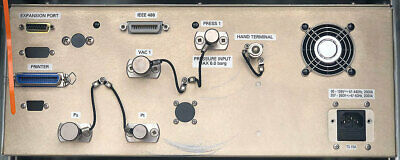

GE Druck ADTS403/ADTS 403 Air Data Test System w/2: LSU100 + PV103R Pump

$ 26399.99

- Description

- Size Guide

Description

GE Druck ADTS 403 Air Data Test System with PV 103R Vacuum/Pressure Supply Pump Unit and 2 LSU 100 Line Switching UnitsComes with what you see in the pictures. If you don't see it, you probably won't get it.

Specifications are from GE Druck and may vary slightly due to upgrades, options, or revisions this unit may or may not have.

This unit is guaranteed to work for 30-days, parts and labor, excluding freight.

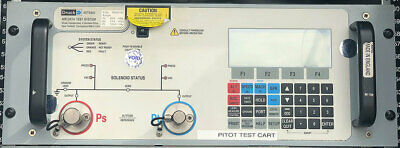

The Main Unit's Serial Number Tag Reads:

Model Number:

ADTS403

Serial Number:

40300105

Range:

Ps:

40.0 inHg

Qc:

73.8 inHg

Pt:

103.4 inHg

ADTS 403 Configuration from GE:

Description:

Free Standing Unit suitable for Rack Mounting, Complete with panel Mounted Keypad and Display.

Altitude:

-30,000 to +80,000 feet

Static Range:

1 to 40 inHg

Pitot Range:

1 to 103 inHg

Option:

C1 - IEEE Interface (SCPI Version)

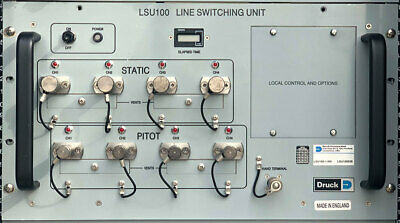

The First Line Switch Unit's Serial Number Tag Reads:

Model Number:

LSU100-1-M0

Serial Number:

LSU100026

The Second Line Switch Unit's Serial Number Tag Reads:

Model Number:

LSU100-1-M0

Serial Number:

LSU100025

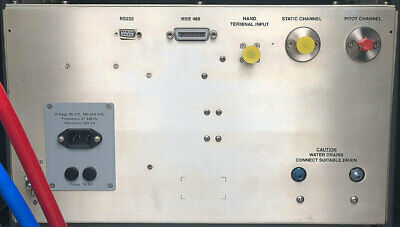

The Pump Unit's Serial Number Tag Reads:

Model Number:

PV103R

Serial Number:

PV10300226

Air Data Test System Features:

High accuracy, RVSM compliant

ATE systems compatible

Protection for unit under test

Compatible with existing IEEE systems

Programmable limits

Pressure/Vacuum Supply Unit:

Supply unit for Air Data Test systems

Dry pumps operating from any AC single phase supply

Opearting life of 30,000 hours between overhauls - simple maintenance

Auxilliary vacuum output

Provides ultimate values compatible with civil and military requirements

Air Data Test System Description:

The ADTS 403 is the latest in a series of reliable, high accuracy, air data test systems designed for the civil aviation industry. The compact, rack-mount design has evolved as a result of GE's continuous research and development, customer feedback and experience gained from manufacturing thousands of automatic pressure controllers. This has enabled performance, ease of maintenance and operational simplicity to be optimized.

The ADTS is a twin-channel, Ps and Pt pressure control system used for the precision calibration/verification of aircraft pilot-statics, compliant with reduced vertical separation minima (RVSM) requirements. A separate pressure/vacuum supply unit type PV103R provides suitable pneumatic supplies.

Fully programmable for a wide range of fixed or rotary wing aircraft, the ADTS 403 enables vital flight instrumentation, such as altimeters, airspeed indicators, rate of climb indicators, Mach meters and air data computers to be quickly and accurately tested.

The ADTS 403 has been designed for 483 mm (19") rack mounting and being only 178 mm (7") (4U) high with a range of IEEE 488 interfaces available it is ideal for use with existing automatic test equipment (ATE) systems.

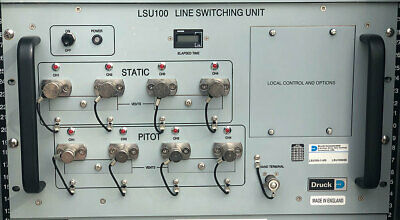

Line Switching Unit Description:

The LSU 100 is a rack-mounted, multi-port unit for the distribution of two channels of controlled pressure.

The unit can be controlled from the front panel key-pad and display (local mode) or through an itnerface (remote mode). The front panel key-pad and display provide information and control selections for the user. The unit can also be cotnrolled through an IEEE SCPI communications interface, RS232 communications interface or a Druck ADTS interface (control port). The front panel contains the operate switch and a mimic panel with LED indicators showing the operation of the solenoid-operated pnuematic valves.

The LSU 100 distributes pitot and static supplies for the external services through two sizes of output connectors. Located on the rear panel of the LSU 100, two input connectors provide for the controlled pitot and static inputs.

Air Data Test System Specifications:

Altitude:

Operating Range:

-19 m to 24,384 m

(1)

(-3,000 ft to 80,000 ft)

Resolution:

0.3 m (1 ft)

Accuracy:

0.9 m (3 ft) at sea level

(2)

, 2.1 m at 9144 m

(2)

(7 ft at 30,000 ft), 9 m at 18,288 m

(2)

(29 ft at 60,000 ft)

Repeatability:

±0.3 m (±1 ft) at sea level, ±0.6 m (±2 ft) at 9 m, ±2.1 m (±7 ft) at 18,288 m

Static Sensor:

Operating Range:

35

(3)

to 1 to 1 to 1355 mbar (1 to 40 inHg) absolute

Resolution:

0.01 mbar (0.0003 inHg)

Accuracy:

±0.1 mbar (0.003 inHg)

Repeatability:

±0.05 mbar (±0.0015 inHg)

Airspeed:

Operating Range:

10 t0 1,000 knots

Resolution:

0.1 kts

Accuracy:

±0.5 kts at 50 kts, ±0.07 kts at 550 kts, ±0.05 kts at 1,000 kts

Repeatability:

±0.4 kts at 50 kts, ±0.02 kts at 550 and 1,000 kts

Pilot Sensor:

Operating Range:

35

(3)

to 3500 mbar (1 to 103 inHg) absolute

Resolution:

0.01 mbar (0.0001 inHg)

Accuracy:

0.01 FS

Repeatability:

0.05 mbar rising to 0.17 mbar (0.0015 inHg rising to 0.005 inHg)

Rate of Climb:

Operating Range:

0 to 1829 m/minute

(5)

, 3500 mbar (1 to 103 inHg) absolute

Resolution:

0.3 m/minute (1 ft/minute)

Accuracy:

±1% of value

Repeatability:

±0.5%

Mach:

Operating Range:

0 to 10

Resolution:

0.001

Accuracy:

Better than 0.005

Repeatability:

0.001 rising to 0.005

Engine Pressure Ratio (EPR):

Operating Range:

0.1 to 10

Resolution:

0.001

Accuracy:

Better than 0.005

Scaling Factors:

Altitude:

ft, meters

Airspeed:

knots, km/hr, mph

Rate of Climb:

ft/min, m/min, m/sec, hm/min

Others:

mbar, inHg, inH2O (4°C, 20°C, 60°F), mmHg, kPa, hPa, psi

Airspeed:

CAS (calibrated), TAS (true_ability to enter temperature)

Overpressure:

Negligible calibration change with up to 1.25x full scale (FS) overload applied

Calibration Stability:

Better than 50 ppm per annum.

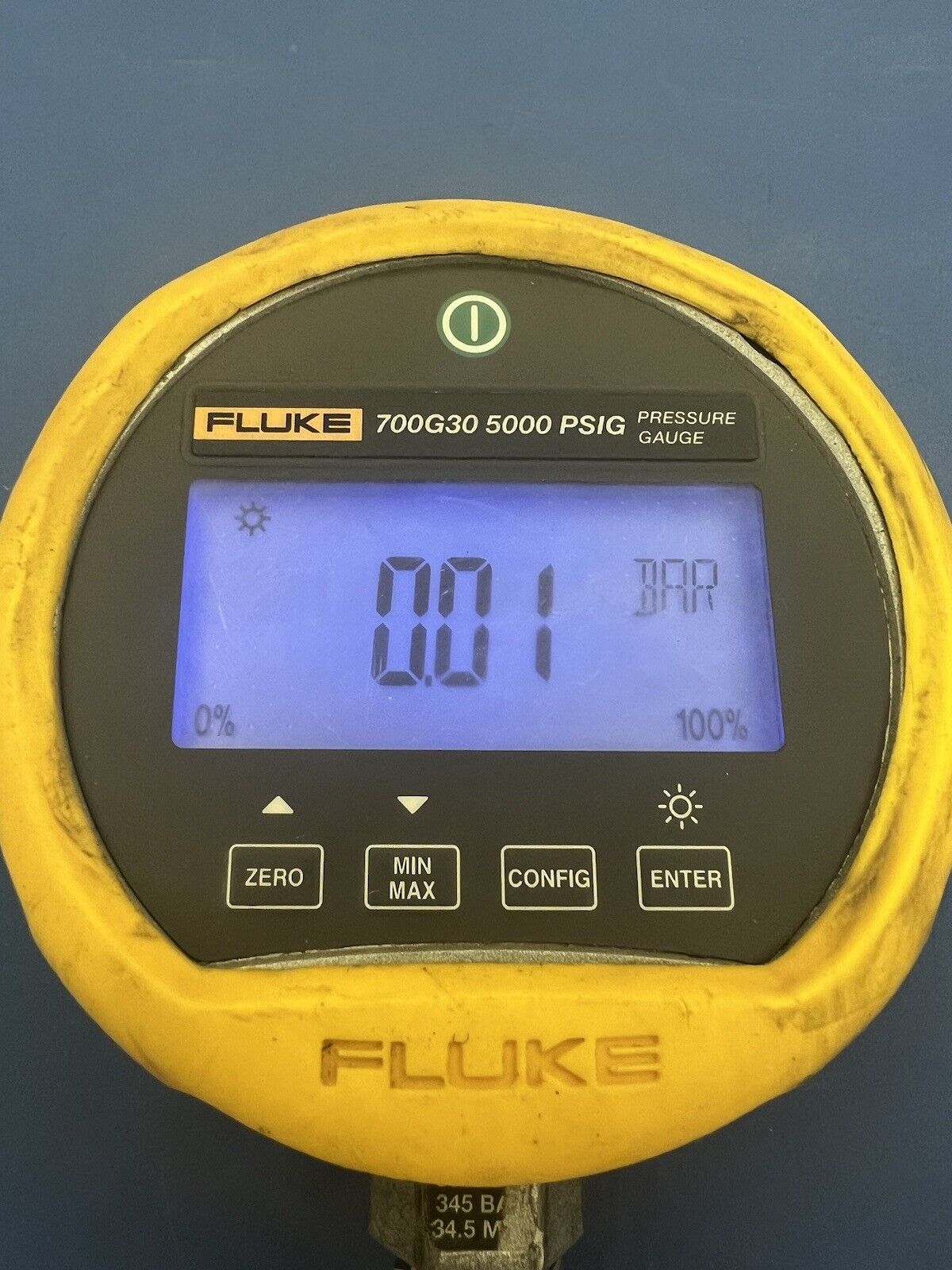

Recalibration:

Simple keypad instruction. 12 month interval suggested. Use of a primary pressure standard is recommended, Ruska primary pitot static tester Model 2468.

Display:

LCD backlit, supertwist/wide angle viewing. 4.8" x 1.6" (122 mm x 41 mm) window with four lines of 20 characters 8 mm (0.3") high.

Response:

Two readings per second display value update. Five readings per second remote interface updates.

Power Supply:

200 VA maximum, nominal 100/120 VAC @ 50/60/400 Hz, Nominal 230 VAC @ 50/60 Hz.

Power Failure Protection:

In the event of a power interruption, the output ports will be vented to ambient conditions safely. On power reconnect, the system is in measure mode.

Self Test:

Integral test routines and reporting for both electrical and pneumatic systems.

Pneumatic Connections - Front and rear panel mounted fittings with blanking caps:

Static:

AN-6 37° flare

Pitot:

AN-4 37° flare

Pneumatic Connections - Rear panel mounted fittings with blanking caps:

Pressure Supply:

AN-4 37° flare

Vacuum Supply:

AN-6 37° flare

Pneumatic Supplies:

For normal use, dry, non-corrosive gases with source pressure at a maximum 25% above specified pressure range. PV 103R recommended (included).

Weight:

13 kg (29 lb) nominal

Dimensions:

483 mm x 432 mm x 178 mm (19" x 17" x 7")

Sealing:

Front panel dustproof. Enclosure complies with CE safety requirements.

Temperature Range:

Calibrated:

5°C to 35°C (41°F to 95°F)

Operating:

0°C to 50°C (32°F to 122°F)

Storage:

-20°C to 70°C (-4°F to 158°F)

Humidity:

0% to 90% non-condensing

Shock and Vibration Compliance:

Designed to meet section 8, EN61010.

Safety Performance:

EN61326 for EMC emissions and immunity. EN61010 for electrical and mechanical safety.

Notes:

1:

32,004 m (105,000 ft) available (control with suitable vacuum pump).

2:

Accuracy at ambient 5°C to 35°C (41°F to 95°F) for 0°C to +50°C (32°F to 122°F) x 1.5.

3:

Lowest calibration point, operates to 0 mbar (0 psi) a

4:

Limits settable to prevent excessive mach. (Civil limit Mach 1).

5:

30,480 m/minute (100,000 ft/minute) rates selectable: limit protected for safety, volume dependent.

Pump Supply Unit Specifications:

Altitude:

Enables 6,000 ft/min rate of climb to 55,000 ft in a volume of 17 liters (1000 cu in) for the static system. Enables 15,000 ft/min rate of climb to 80,000 ft into a volume of 4 liters (240 cu in) for the static system.

Airspeed:

Enables a rate of 1 Mach/minute to 550 knots into a volume of 10 liters (600 cu in) for the pitot total system. Enables a rate of 900 knots/minute to 850 knots in a volume of 2 liters (120 cu in) for the pitot total system.

Power Supply:

88-260 VAC, 47 to 440 Hz, 300 VA

Weight:

9.5 kg (21 lb)

Case Dimensions:

438 mm W x 178 mm H x 266 mm D (19" x 7" x 10.5")

Maximum Vacuum:

20 mbar absolute (0.49 inHg absolute) (85,000 ft)

Maximum Pressure:

3.5 bar gauge (100 inHg gauge).

Line Switch Unit Specifications:

Size:

Standard 19" rack front panel 6U high (10.5"). Depth behind front panel 269 mm (10.6")

Weight:

17.3 kg (38 lb)

Power Supply:

Single phase AC in the range of 88-265 VAC over the frequency range 47-440 Hz. No switching required - all automatic. 200 VA.

Pressure Fittings:

Static:

AN-6

Pitot:

AN-4

Pressure Range:

Static:

0 to 3500 mbar (0 to 103 inHg)

Pitot:

0 to 3500 mbar (0 to 103 inHg)

Temperature Range:

Operating:

+5°C to +55°C

Storage:

-40°C to +70°C

0.00 minimum for packaging, handling, and order processing. Shipping to be determined by destination.

Prior to shipment I will need to know the following information (filled out on a form that I will send you) for International Customers or Packages/Freight being Forwarded internationally. International customers may also be subject to a freight forwarder form if applicable.:

(1) Are you the end-user of this item?

(2) If you are not the ultimate end-user of the item, please state the ultimate end user's name.

(3) What is the ultimate country destination?

03/09/19